Introduction to the Compact Track Loader Buying Process

Table of Contents

Table of Contents

- Introduction

- Trends

- Specs

- Features

- Attachments

- Choosing a Dealer

Introduction

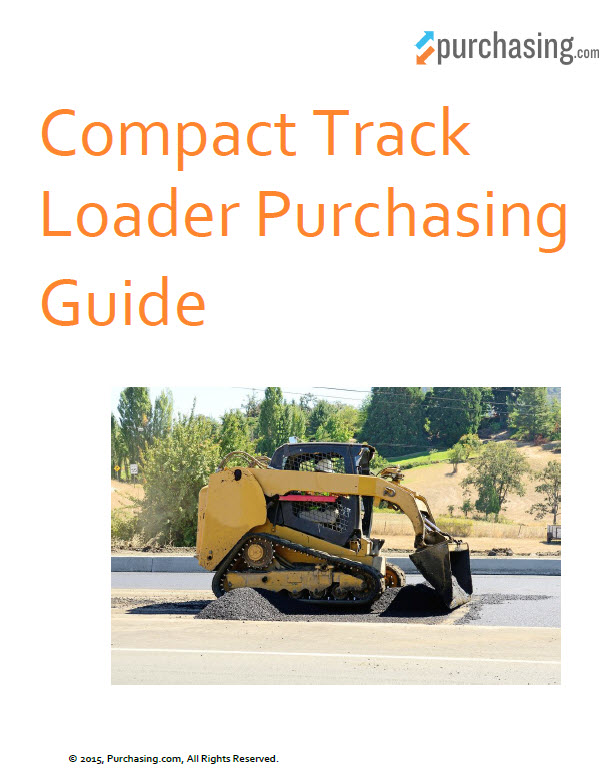

Compact track loaders combine the productivity of a bulldozer with the wide-ranging compatibility of a skid steer. Compressed into one of the smallest frames within the earth moving category, track loaders are now widely used throughout agriculture, landscaping, facilities maintenance, and military environments for an endless variety of tasks.

Offering one of the most advantageous horsepower-to-weight ratios, these machines have been engineered for everything from small-scale home and building construction to creating a fire line and clearing debris from a war zone. They feature higher degrees of pushing force and greater flotation which result in cost-effective productivity with minimal disturbance to the work area.

Purchasing considerations

Like most machines in the earth moving category, compact track loaders are available in a range of power outputs and operating capacities. Whether recently introduced as a new line or reintroduced as a second generation, current models will be fully compatible with EPA Tier 4 emission control requirements.

Your jobsite location will largely determine the type and size you need. But there are additional specs to consider as well, including joystick controls, weight limitations, and even cab design. You'll find out more on these purchase considerations (and how they affect you) within the Specs section of this guide.

This guide addresses the major elements that go into the purchase of a new or used compact track loader. We've also compiled some data on choosing a quality dealer to ensure you get the best post-sale support and highest return on your investment. But before we get into the technical data, it's important to consider the trends that are shaping the purchase of compact track loader.

Trends

The biggest trend in compact track loaders is one that echoes throughout the earth moving category: compatibility. Often purchased to perform a wide range of tasks on a single jobsite, track loaders are similar to skid steers in a number of ways and, in some instances, can be used interchangeably. But each machine offers unique aspects in design and performance, making one better suited to some applications than the other.

Here's how they compare:

Here's how they compare:

Compact track loaders

Even though they've been adopted by a number of industrial and construction applications, compact track loaders remain the machine of choice for farming and landscaping; much of this favoritism is due to the machine's high level of pushing force and improved flotation. In combination with substantially lighter weights, these features allow a track loader to provide heavier-duty operation while still remaining compact and minimally disruptive to the terrain and surrounding environment.

Compact track loader strengths:

- Greater lift capacity, capping out around 3,800 lbs, versus a skid steer that usually accommodates around 2,500 lbs at max

- Greater pushing and digging force through a more powerful diesel engine capable of up to 90 hp, versus 74 hp in a skid steer

- More comfortable ride on uneven or rough terrain

- Ideal for pushing and grading due to low ground pressure

Skid steers

The other side of the coin isn't as robust in terms of output. But what it lacks in horsepower, the skid steer makes up for in performance, design, and compatibility. Easily the best machine for extreme maneuverability requirements, skid steers tend to offer a wider range of sizes, weights, and standard functionality - especially crucial for those needing max reach and clearance for lift and dump operations. They are also famous for the extensive line of quick-couple attachments they accept, with up to 100 different tools available from major brands and third-party attachment manufacturers.

Skid steer strengths:

Skid steer strengths:

- Higher reach for lift/dump heights, up to 12 feet (compared to track loaders that typically cap out around 10 feet)

- More compatible with hard work surfaces, including asphalt, concrete, or rock (these conditions can cost 20% to 30% more for each job when using a track loader due to track wear)

- Increased versatility through a wider set of attachment options (more than any other machine)

- Advanced technology and design, including automatic functions, real-time monitoring, and ergonomic cab layout

New or used?

Another significant trend among many prospective owners is the choice between new and used equipment. This decision has come to the forefront in recent years due to fluctuations in economic activity, giving used track loaders an edge for the low upfront cost and high rate of return they provide. With a price tag that ranges between 30% to 50% less than a new machine, used compact track loaders are fully reliable and backed by a guarantee and post-sale support (when purchased through a professional dealer).

For example, it's not uncommon to find a used compact track loader manufactured between 2011 and 2012 with 500 to 1,500 work hours on its meter going for around $52,000 to $55,000. Taking a step further back, used machines manufactured between 2006 and 2008 with 900 to 2,200 work hours can be found for $22,000 to $24,000. These prices are in contrast to newly manufactured machines that start around $65,000 and go as high as $90,000.

But depending on your intended use and the structure of your business, a new machine may make more sense. And this is actually where the biggest difference between used and new track loaders comes into play: technology.

New machines feature the latest technological innovations, many of which have been incorporated into the controls, monitoring functions, and the engine - all of which are designed to tweak performance. While part-time users may not notice any savings in comparison to a used machine, large landscaping outfits, industrial farms, and those who use the track loader full-time for light-duty construction and similar applications almost certainly will.

For example, the conversion to Tier 4 engines cuts the level of exhaust emissions. But it also reportedly improves performance as well. Manufacturers cite efficiencies achieved through increased power (up to 15% more in some cases) and torque due to engine reconfiguration, all of which add up to lower operating costs. In addition, diesel fuel tanks have been redesigned to accommodate more fuel, enabling a loader to run up to 10 hours without a refuel.

- Purchasing recommendation: For part-time or seasonal use, used compact track loaders are probably the more cost-effective way to go. Full-time operations and those employing compact track loaders as part of a fleet or to supplement other equipment will benefit greater from the advancements in a new machine.

Specs

Unlike the spread you find in other types of earth moving equipment, the range of specs for compact track loaders is relatively narrow. In fact, an average output of 60 hp and an operating capacity of about 3,100 lbs (at 50% tip) are all that separate the smallest machine from the largest in this category. Below, we'll review important specifications you should know.

Max lift/dump

If you're looking for elevated lift and dump heights, a wheeled loader or bulldozer would probably be the way to go. But for tasks that require limited heights, such as stockpiling or loading and unloading a truck, a compact track loader gets the job done quickly and more cost-effectively than larger equipment.

When comparing models, take the unit's max lift and dump capabilities in mind as they relate to the common tasks on your jobsite. Any requirements above 8 feet should be relegated to a larger piece of equipment.

Reach at max lift/dump

Similar to the max lift/dump consideration, many jobsites require a certain degree of reach when retrieving or placing loads - warehouse applications and areas with immovable objects or structures being two primary examples.

In these instances, a track loader can reach a little over 2 feet, which is usually enough to place materials beyond a barrier wall or into a specific area for finish grading. For reach requirements beyond 2 feet, forklifts and aerial lifts can provide much greater capabilities.

Operating capacity (35% tip)

Operating capacity is one of the key areas that determines the machine's ROI. Start by evaluating the average load you expect to haul and which you need more of: lift height or reach. With this information, you'll choose between a track loader that offers arms featuring either a vertical or radial lift path.

Vertical lift path models provide higher lift capacities and up to 40% more reach in some cases. But they also cost 10% more than a radial model. Track loaders with a radial design lift in an arc, providing better reach at minimal heights.

If the average load is below minimum operating capacity (35% in this case), a radial unit is probably your best option. Common tasks include loading and unloading trucks, spreading gravel, backfilling, and grading.

Operating capacity (50% tip)

As detailed above, your needs related to operating capacity determine which type of machine you select: one with a vertical lift path or one with a radial lift path. When you're looking to transport heavier loads, such as boulders, lumber, or heavy palletized materials, a machine with vertical lift path may provide the most cost-effective operation.

In fact, those looking for machines with heavier capacities (up to 50% tip in this case) may be able to increase their productivity by 15% according to some estimates. It's also worth noting that track loaders with a vertical lift path are more effective when using an auger as the machine keeps the auger's path vertical during operation.

Operating weight and tipping load

When evaluating weights, know that the machine's rated operating capacity is half of its tipping load. Defined by the manufacturer, this assumes the machine is operating on a hard, stable surface. But unless you intend to operate your equipment solely in a warehouse or loading dock, this will rarely be the case.

If the track loader you select will be required to transport goods at height, in the mud or sand, or around a jobsite with uneven terrain (slopes being a common example), tipping load is a major concern as these conditions will impact the machine's center of gravity, causing it to tip.

Again, know your work environment and average load, then give yourself a safety cushion to account for the unforeseen.

Again, know your work environment and average load, then give yourself a safety cushion to account for the unforeseen.

Ground pressure

Post-project repairs to the grounds around your jobsite can quickly take a chunk out of your profitability. This makes ground pressure critical to many operators, especially those using a track loader for landscaping.

Compact track loaders are known for their low ground pressure and superior flotation, especially when compared to a skid steer. Providing minimal disturbance to turf and other costly terrain, track loaders distribute their weight over a larger area, making them ideal for sensitive projects like fine grading, and irrigation installation.

While each type of terrain will be different, manufacturers for sod and artificial turf recommend no vehicle weighing over 300 lbs be parked on the terrain for extended periods of time, and especially not during warmer temperatures or wet conditions.

Engine power

According to representatives from major manufacturers, new engines actually provide increased power that translates to better hydraulic performance - more than 10% better in some cases. This directly impacts the output of attachments.

New engines have also been manufactured with greater levels of torque through advancements in electronic engine controls, enabling smaller machines to tackle bigger jobs. This development allows you to buy a machine with a higher torque rate and run the engine at a lower, more fuel-efficient speed.

Keep horsepower and torque in mind when comparing track loaders, especially when coupling them with heavy-duty attachments like flail cutters, trenchers, and stump grinders.

Dimensions

If you've ever tried to swing a hammer in a restricted space, you know how quickly it limits your productivity. The same is true of a track loader. It's size will determine your productivity and cost-effectiveness on every job.

In general, large construction companies and agricultural outfits will benefit from the largest models as they are designed to move around in wide open spaces. Smaller machines are better suited to smaller landscaping tasks, grounds maintenance, and residential construction. Plus, smaller units are a lot easier to transport. They can usually be towed by a standard truck on a small trailer with a second piece of equipment - making them ideal for a single individual or small business.

Depending on the nature of your jobsite, mini excavators are also an option. Capable of 360o rotation and offering a more compact frame (3' (w) x 7' (h) for example), they also provide the digging depths that compact track loaders lack.

QUICK COMPARISON

- Max Lift/Dump: 7.5 to 8.75 feet

- Reach at Max Lift/Dump: 1.9 to 2.5 feet

- Operating Capacity (35% Tip): 665 to 2,660 lbs

- Operating Capacity (50% Tip): 950 to 4,200 lbs

- Tipping Load: 1,900 to 7,600 lbs

- Operating Weight: 3,600 to 10,200 lbs

- Ground Pressure: 3 to 4.4 psi

- Engine Power: 32 to 90 hp

- Dimensions: 4' (w) x 6.4' (h) to 5.75' (w) x 13' (h)

Newest models

Here's a quick comparison on some of the latest models to hit the market, including many of the specs detailed above and an average price range for each.

[table]

MFR/Model, Horsepower, Tipping Load, "Operating Capacity (35% - 50% tip)", Fuel Tank (gal), Emission Controls, Estimated Cost (New and Used)

Terex R070T, 32.7 hp, "1,900 lbs", 665 lbs, 10, Tier 4, "$33,000 - $41,000"

Bobcat T590, 66 hp, "6,000 lbs", "2,100 - 3,000 lbs", 24.75, Tier 4, "$36,000 - $56,000"

John Deere 319E, 69 hp, "6,143 lbs", "2,150 lbs", 20, Tier 4, "$21,000 - $60,000"

Gehl RT175 GEN:2, 69.9 hp, "5,000 lbs", "1,750 - 2,500 lbs", 24, Tier 4, "$31,000 - $46,000"

Kubota SVL75-2, 74 hp, "2,980 lbs", "1,043 - 1,490 lbs", 24.6, Tier 4, "$33,000 - $65,000"

CAT 279C Series 2, 82 hp, "2,941 lbs", "1,016 - 1,451 lbs", 26, Tier 4, "$29,000 - $60,000"

Case TV380, 90 hp, "7,900 lbs", "2,660 - 3,800 lbs", 25.5 , Tier 4, "$40,000 - $93,000"

[/table]

Back to top

Features

Mechanical specifications aren't the only thing that determines productivity on a jobsite. In fact, it's arguably not even the most important factor. Operator comfort and conveniences associated with the machine's operation have a huge impact on how quickly and how well tasks get accomplished.

Mechanical specifications aren't the only thing that determines productivity on a jobsite. In fact, it's arguably not even the most important factor. Operator comfort and conveniences associated with the machine's operation have a huge impact on how quickly and how well tasks get accomplished.

Here's an in-depth look at some of the most popular features.

Cab design

Cab design has taken huge leaps forward in the past 10 years, with developments mainly centered on operator comfort and safety. New models feature a cab-forward design that positions the operator closer to the workspace and attachment. In doing so, he or she is able to work more efficiently and avoid accidents that result from poor visibility.

Speaking of visibility, windows have been redesigned to provide a wider panorama of the work area, with rear windows about 15% larger and top windows almost 50% larger in comparison to previous generations. Plus, if width isn't a concern for you, some brands have redesigned the spacing and width of the loader's arms, allowing for a roomier cab that offers storage space and more leg-room.

Joystick control

While the integration of a joystick isn't exactly new, it's quickly become the preferred method of operation. Modern compact track loaders are operated via a seat-mounted joystick that provides enhanced comfort during operation by moving in tandem with the seat as it moves up and down.

Other models include the joystick mounted independently of the seat but make its position adjustable to the individual operator. Whether mounted on the seat or another part of the machine, all mechanics and hydraulic attachments are operated by the joystick, with fingertip controls that simplify operation.

Radio remote control

Designed for working in dangerous areas such as chemical plants, demolition sites, forest fires, and warzones, the radio remote transmitter provides the ability to safely operate the loader from up to 1,500 feet away. Using joystick control, the system works on a rechargeable battery and runs for up to 15 hours on a single charge. This feature is typically not standard, though many machines are now "remote control ready."

Intuitive instrument panel

Intelligence is the key to any successful operation. And this is one area in which compact track loaders are attempting to catch-up their somewhat more versatile cousin, the skid steer. New track loader instrument panels, or "instrument clusters" as they're sometimes called, provide real-time data on the machine's operational status as well as a number of programmable security codes and anti-theft technology. With a bright LED screen, the operator can also select from a range of available languages and measurements displayed as English or metric.

Climate control

Cab comfort has a huge impact on productivity, especially in extreme climates when windows tend to fog up or ice over. Most new compact track loaders include a range of heating and air conditioning options that are built into the machine itself so as not to expand its profile. Similar to a car or standard truck, vents can be manually directed within the cab while facilitating airflow throughout to promote defrosting and demisting.

Cab pressurization is another climate control option, but one that may not be standard on some machines - worthwhile though it may be. Pressurization seals the cab from external dust and debris flying in the air outside. This function keeps the air breathable for the operator and also protects instrument panels and other cab components that would be susceptible to a build-up of dust.

Back to top

Attachments

Compact track loaders have been developed to accept a range of attachments. These add-ons transform a single loader into a fleet of tiny earth moving machines. Below are some of the most popular attachments, broken down by application, and what you can expect to pay for each.

Land-clearing attachments

- Rotary cutter - Featuring doubled-edged steel blades and a front guard that prevents rocks and other debris from flying into the surrounding area, these cutters range from 5'x5' to 7'x7' and take huge swaths out of the work area in seconds. Expect to pay: $900 to $13,000 depending on the brand and year of manufacture, with most new units starting around $5,000.

- Stump grinder - With a cutting head speed in the neighborhood of 900 RPMs, this attachment chews through stumps up to 5 feet wide in a single swing. It can also cut above ground (to about 18 inches) and below ground (to about 20 inches). Expect to pay: $6,000 to $9,000

- Flail cutter - Combining the functionalities of a mower and mulcher, a flail cutter can mow grass, brush, and even small trees up to 3 inches in diameter then distribute the remains evenly over the ground. Expect to pay $1,700 to $3,300.

- Chipper - Sometimes referred to as a "brush chipper," a compact track loader chipper can grind up brush, branches, and entire trees up to 5 inches in diameter, reducing the volume by 10 to 1. Plus, given its narrow design, it fits into spaces a full-size chipper cannot. Expect to pay: $7,500 to $10,000.

- Grapple buckets - Upgrade your standard bucket with a set of clamps that keep logs and other oddly shaped debris firmly in place during transport. Bucket weights range from 1,100 to 1,300 lbs and feature clamps that are designed to grip evenly on the load with a force of up to 3,000 lbs at 2,000 psi. Expect to pay: $2,800 to $3,700.

Site preparation attachments

- Soil conditioners - Used to prepare terrain for the laying of a foundation, soil conditioners help grade and level the terrain while simultaneously removing rocks and other debris mixed in with the dirt. Most can be used when operating in both forward and reverse and can perform on slopes with an angle of up to 25o. Expect to pay: $4,600 to $8,600.

- Dozer blades - The standard for most compact track loaders, dozers blades shove tons of dirt, rock, and debris around the jobsite. Many allow angling from 15 o to 30 o and come in widths ranging from 69 to 96 inches. Expect to pay: $5,400 to $5,700 for standard models.

- Box blades - Designed more for landscaping than moving materials, a box blade includes two foam-filled tires that allow the blade to float slightly above the terrain, ensuring a smoother end result. Note: this attachment is designed primarily for flat surfaces. Expect to pay: $2,500 to $8,300.

- Landplanes - When prepping a field or similar area, a landplane can quickly strip away sod, rocks, and debris while acting like a bucket that shoves the materials to one side of the jobsite. Widths range from 48 to 78 inches and the attachment performs functions in both forward and reverse motion. Expect to pay: $900 to $3,600.

- Laser-guided graders - Sometimes referred to "automatic grade control," a laser-guided grader provides a more accurate finished terrain and is meant to supplement a standard grader or box blade attachment, reportedly improving efficiency by up to 70%. Two types are available, including an automatic laser that uses a laser transmitter mounted in a fixed position on the jobsite or a sonic/slope system that uses a sonic tracer mounted to the side of the loader. The latter is more accurate in areas with trees, buildings, and other objects that would obstruct the sightline of a laser transmitter. Expect to pay: $7,200 to $13,800 for the tech alone and separately for the grader or box blade.

- Tillers - Designed to prepare rough terrain for seed and other plantings, a tiller breaks up large chunks of earth into smooth, evenly tilled soil. Some models include offset mounting that enables tilling next to buildings, sheds, trees, or other immoveable objects. Widths range from 40 to 76 inches. Expect to pay: $1,100 to $4,000.

- Sod layers and seeders - Expediting two of the most time-consuming process in landscaping and agriculture, sod layers and seeders all but eliminate the need for a large crew. Sod layers carry and roll sod bundles ranging from 24 to 48 inches, with a locking mechanism that prevents the accidental unrolling of the bundle. Seeders feature automated metering that's fully adjustable, producing a high degree of accuracy on up to 2 acres per hour. Some are bi-directional while others include rollers on the rear of the attachment to cover up the seeds. Expect to pay: $1,700 to $3,000 for a sod layer and $4,700 to $8,300 for a seeder.

Planting attachments

- Power augers - Whether you're building a fence or planting trees and shrubbery, a power auger can bore out a hole from 6 to 48 inches in diameter in just minutes. Most units can pivot horizontally as well as vertically and are powered either by a chain drive or planetary drive. Expect to pay: $1,800 to $2,800 for the attachment itself and $400 to $650 per blade.

- Tree spades - These are handy for quickly and gently digging, moving, or transplanting trees ranging between 1 and 5 inches in diameter. Dig depths range from 20 to 35 inches. Plus, some attachments feature adjustable legs that allow the digging of a variety of tree balls. Expect to pay: $5,000 to $32,500 depending on the make and size, with new models starting in the $10,000 range.

Choosing a Dealer

More than any other aspect of the purchase process, choosing a quality dealer means the difference between a machine that performs adequately and one that elevates your business - custom-fit to your specific needs - and remains highly cost-effective for as long as you own it. While each dealership offers a range of products and services, there are a few standards to be on the lookout for. Here's how to find the dealer that's best suited to you.

Training

Many established dealers provide in-person training that covers the operational functions of the machine itself as well as general safety and best practices. These guidelines are designed to provide more than just "how-to." Based on years of experience, often within your niche, they can save you and your operators countless time on specific tasks while helping to avoid common pitfalls.

In addition to dealer training, some major manufactures offer support materials that often encompass online databases, DVDs, and printed workbooks and handouts. Bobcat is a great example. Through their website, they provide safety videos, training packets (for purchase), and materials designed for track loader rentals.

Questions related to training:

Questions related to training:

- Training provided? If so, is it in-house or at an off-site training facility?

- What does the training cover?

- Additional costs?

Support and maintenance

Post-sale support can take shape in a number of different ways. Most dealerships provide extensive routine service and maintenance programs for both new and used track loaders to ensure your machine remains running smoothly and avoids unexpected breakdowns.

This level of support is summarized in a service level agreement (SLA), defining everything from the service intervals to the costs associated with parts and labor. These terms directly affect the cost-effectiveness of the investment. So give preference to the SLA that is comprehensive and best meets your needs.

Questions related to dealer support:

- Maintenance schedule and hours between each service interval?

- Cost of each type of service (if the machine is not under warranty)?

- Service location - on-site or at a remote facility?

- Estimated turnaround for service?

- Parts used for replacement? [Note: manufacturer recommendations are best.]

Get Quotes

- We contact sellers

- They compete for your business

Inspection tips

Not everything can be determined over the phone or through an in-person facility visit. So unless you have working knowledge of a compact track loader, including all of the mechanics and individual parts, it's always best to consult with a qualified service technician before purchase. Even though the machine may be covered under warranty and backed by a service agreement, there are still a number of costly repairs that may fall outside those contracts when buying a used machine. A tech will be able to quickly spot problems and let you know whether the deal is as good as it seems.

In general, here's what they'll be looking for:

- Structural integrity - The body of the loader should be free of cracks or dents as these may indicate compromises to structural integrity. On a compact track loader, this is of particular concern on the undercarriage which can quickly indicate how much abuse the machine has seen.

- Engine & leaks - Oil leaks are never a good sign. On a track loader, bucket tilt cylinders and all hydraulic hoses should be checked for damage. Leaks in the engine compartment are the worst as they can damage the radiator and wiring.

- Tracks - As mentioned in the Trends section, compact track loaders have a tougher time on hard work surfaces as it tends to wear down the tracks at a much faster rate. Costing anywhere from $400 to $3,000 for a replacement set, the tracks on a used machine should have at least 40% of their wear left.

- Service intervals - Getting a quality used machine isn't hit or miss. Much of what contributes to a good used model is the previous owner's adherence to a service routine. Filters should all have a date and hour marked for their last date of service. Compare this date with the machine's work hours to determine whether it has been serviced within the manufacturer's recommendations.